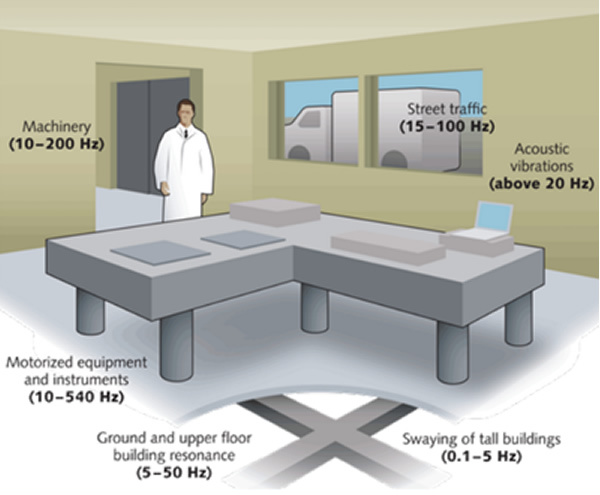

If the application requires working with feature sizes down to 0 1 mm vc e however vibration control equipment would be needed in order to achieve an environment conducive to this type of measurement.

Floor vibration measurement equipment.

Sophisticated finite element analysis fea techniques can be used to solve floor vibration problems which can affect people in a high rise office boardroom or disturb sensitive medical and industrial equipment and to design isolation systems for both small equipment and entire buildings.

Nuisance human occupants of a building can perceive very low amplitudes of vibration and depending on the circumstances even modest doses of floor vibration can cause discomfort or alarm.

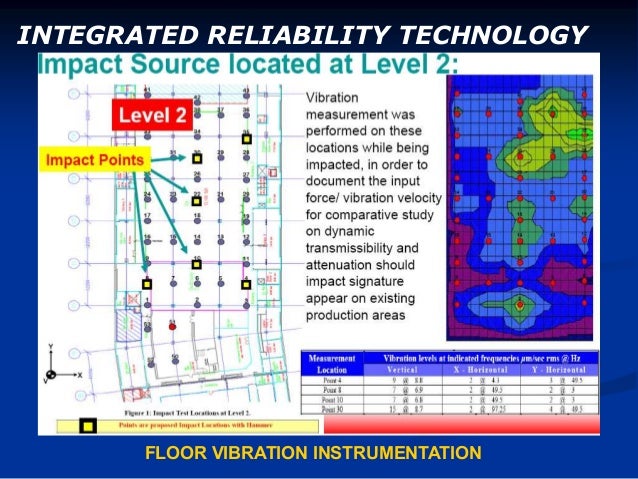

By carrying out a floor vibration measurement the plant owner can identify the best site to place the sensitive instrument.

90 9 90 shipping.

The measurement of vibration on a floor is useful for the following scenarios i for certain plants people walking by or pushing a trolley can affect the operation of sensitive instruments such as a high electron microscope.

At rs components we offer a wide range of sound and vibration measurement equipment from market leading suppliers.

Brands include castle casella cel testo and our own brand rs pro.

Vibration meters rion vm 82.

In this case vibration isolators would be required to attenuate the floor vibrations.

Gti i pad vibration analyzer.

Extech s vb300 vibration recorder.

Gti i pad vibration analyzer with balancing kit.

Digital vibration meter piezoelectric vibrometer gauge colored flip display acceleration velocity and displacement measurement with short long probe portable symmetrical shape by gain express 118 90 118.

It s definitely limited in sample rate up to 200 hz and total storage 4mbit or 112k samples per axis but for some applications this as adequate.

Whether you re looking for calibrators sound level meters stethoscopes or vibration meters you ll find everything you need in one place.

In this mode the vibration reaches maximum amplitude in one position an antinode at mid span of the beam.

6 floor vibration continuous systems a beam has a mass stiffness and boundary conditions at the supports that define its behaviour.

The system has a fundamental frequency which corresponds to the first lowest mode of vibration.

Certain items of precision equipment are also extremely sensitive to vibration.

Coming in at less than 300 it can be a great first option at quantifying your vibration environment.

Vibration mete with triaxial hand arm or seat accelerometer norsonic nor136.

Using these vibration sensors and our analysis equipment we measure the frequencies and amplitudes of the floor vibrations at the site where the equipment will be installed.

.jpg)